Blog

XY-TEK is a high-tech company specializing in the development, manufacturing, and sales of accurate and reliable ultrasonic flow sensors/flow meters. We specialize in flow rate measurement for small tubing and low flow rates in medical devices, bioprocessing, beverage and drink filling, industry automation, etc. XY-TEK also offers ultrasonic flow sensors, vortex flow meters, and bubble detectors OEM.

CPD Clamp-on Ultrasonic Flow Meter in PCB Cleaning Equipment: Enhancing Cleaning Quality and Process Stability

PCB Cleaning Equipment Introduction

PCB cleaning is a critical process in integrated circuit manufacturing, crucial to multiple PCB production processes. As PCB manufacturing processes continue to evolve, the sensitivity of PCB surfaces to impurity particles has significantly increased, posing new challenges to cleaning processes and cleaning equipment.

PCB cleaning technologies are mainly divided into dry cleaning and wet cleaning categories, with wet cleaning becoming the mainstream due to its efficient and uniform cleaning effects, applied across procedures such as soldering and etching.

Wet cleaning uses chemical cleaning solutions, ultra-pure water, or drying solvents (such as isopropyl alcohol, IPA) to remove flux residues, dust, organic matter, metal contaminants, and other impurity particles.

For PCB cleaning equipment manufacturers, achieving high-accuracy control of cleaning fluid flow to ensure thorough cleaning of PCBs while avoiding damage to circuit patterns on the PCBs is key to enhancing equipment competitiveness.

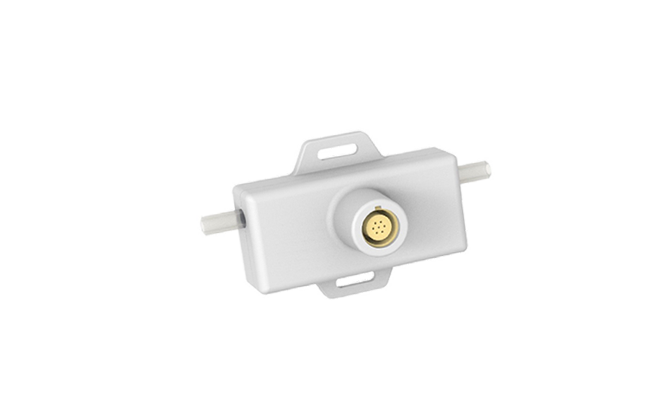

We will analyze how XY-TEK's CPD clamp-on ultrasonic flow sensor plays a pivotal role in PCB cleaning equipment, based on the customer's flow rate measurement requirement for cleaning equipment.

Flow Rate Measurement Challenges for a PCB Cleaning Equipment Customer

As a supplier to a Chinese PCB assembly plant, W company, a PCB cleaning equipment manufacturer, encountered the following cleaning fluid flow rate measurement challenges during the development of cleaning machines for advanced processes:

1. Insufficient Cleaning Fluid Flow Measurement Accuracy Leading to PCB Surface Damage

Traditional flow rate measurement methods struggle to accurately control the output flow of cleaning fluid in real time, resulting in unstable flushing intensity due to flow fluctuations, which can easily damage circuit patterns on PCB surfaces. The lack of real-time flow rate measurement prevents dynamic adjustment and optimization of cleaning fluid flow.

2. Safety Hazards in Cleaning Fluid Supply Systems

In the event of abnormalities in the fluid supply system, emergency power shutdowns cause retained liquid to generate bubbles, increasing pipeline pressure. The fluid supply system lacks flow anomaly and bubble detection, making it impossible to promptly warn and address risks of pipeline rupture due to excessive pressure.

3. Response Delays in Magnetic Levitation Pump for Cleaning Fluid Medium Switching

Wet cleaning processes require alternating use of cleaning media with different characteristics, where differences in viscosity, density, corrosiveness, and other properties are significant. Existing equipment uses magnetic levitation pumps in fixed-parameter operation modes, leading to flow fluctuations during medium switching. Traditional flow sensors have response delays, making it difficult to quickly feed back flow fluctuations caused by medium changes.

4. Contamination Risks in Ultrapure Media

Invasive flow sensors / flow meters come into direct contact with cleaning fluid components such as ultrapure water, potentially introducing metal ions from the sensor's internal structure or creating particle retention points, which fail to meet the ultra-pure requirements of PCB assembly processes.

5. Extremely Short Equipment Maintenance Windows

Cleaning production lines requires 7×24-hour operation, so flow sensors/flow meters in the equipment must minimize frequent maintenance and disassembly that could cause downtime.

Application of Clamp-on Flow Meter in PCB Cleaning Equipment

To address the above challenges, the customer integrated the CPD clamp-on ultrasonic flow sensor / flow meter as the core flow measurement component, enabling innovative applications in multiple key aspects of PCB cleaning equipment.

1. Accurate measurement of Cleaning Fluid Flow Rate

The clamp-on ultrasonic flow sensors / flow meters are integrated into the cleaning fluid flow management module to measure the flow of liquid used in real time, with measurement results repeatability reaching ±0.1%. Through collaborative operation with flow control valves and the CPD clamp-on flow meter, the fluid management module accurately controls the cleaning fluid speed, enabling dynamic adjustment of cleaning fluid flushing intensity to balance cleaning effectiveness and PCB protection.

2. Safety Monitoring of Cleaning Fluid in Circulation Systems

The CPD clamp-on ultrasonic flow sensor is installed in the cleaning fluid circulation tubing to monitor the circulation flow of heated liquid in real time, with preset flow threshold monitoring. When the flow rate falls below the threshold, it automatically increases the booster pump output power; when the flow rate exceeds the threshold, it outputs an anomaly alarm and automatically reduces the booster pump power. Flow anomaly alarms prevent overheating of retained liquid in the heater, eliminating risks of tubing rupture.

3. Adaptive Control of Magnetic Levitation Pumps

The CPD clamp on flow sensor / flow meter is installed at the outlet of the magnetic levitation pump to monitor flow changes during different medium switches in real time, with millisecond-level response speed. Flow data fluctuations caused by medium changes are fed back to the magnetic levitation pump control system, enabling adaptive parameter adjustments based on flow feedback.

4. Contamination-Free Measurement of Ultra-pure Media

Non-contact measurement ensures zero contact between the sensor and cleaning fluid, avoiding contamination of ultrapure water, acid-alkali solutions, and other media by the sensor's internal structure.

5. Intelligent Early Warning and Fault Diagnosis

Supports real-time flow anomaly alarming, historical flow data recording and analysis, and remote monitoring and diagnosis of flow data, providing data support for predictive maintenance of cleaning equipment.

Customer Value

1. Significant Improvement in Cleaning Process Precision and Safety

Enhanced cleaning fluid flow control accuracy significantly reduces PCB damage rates. Real-time flow rate measurement ensures process stability, with anomaly response times shortened to milliseconds.

2. Optimized Cleaning Effectiveness and Equipment Reliability

Shortened response times for magnetic levitation pump medium switching enhance the cleaning equipment's ability to adapt to different process media, significantly improving cleaning quality.

3. Reduced Operational Costs and Maintenance Needs

Non-contact measurement reduces sensor maintenance requirements, lowering overall equipment maintenance costs. Supports predictive maintenance, reducing unexpected failure rates.

4. Support for Advanced Process Needs

Meets the stringent requirements for flow measurement in cleaning processes of advanced manufacturing.

5. Enhanced Product Yield and Competitiveness

Reduces PCB cleaning defect rates, improving the market competitiveness of cleaning equipment.

Product Features

1. High-Accuracy Non-invasive Flow Rate Measurement

True non-invasive flow rate measurement with 0 contact between the flow sensor and cleaning medium, no metal ion precipitation, no particle generation, and no dead corners for residue. Measurement repeatability of ±0.1% FS, meeting the stringent requirements of PCB assembly processes.

2. Fast Response and High Reliability

Millisecond-level response speed, supporting real-time closed-loop control, with no moving parts, maintenance-free design, and excellent long-term stability.

3. Multi-Medium Adaptability

Capable of measuring various media such as ultra-pure water and acid-alkali solutions, supporting liquid temperature ranges of 0-90°C. Can be clamped onto rigid plastic tubing (PFA, PTFE, PP, etc.) with outer diameters of 6-26mm.

4. Ultra-pure Liquid Flow Rate Measurement

The flow rate measurement process poses no contamination risk. Corrosion-resistant housing with easy-to-clean surface design, suitable for PCB assembly manufacturing environments.

5. Integrated Intelligent Functions

Built-in bubble detection function for real-time detection of tiny bubbles with diameters ≥1/3 of the pipe inner diameter. Automatic flow anomaly alarming, support for flow data recording and traceability, and remote monitoring and configuration of flow data.

6. Convenient Installation and Maintenance

Clamp-on installation requires no pipeline cutting and can be completed in minutes. Supports online installation without equipment downtime.

7. Strong Anti-Interference Capability

Anti-vibration and anti-electromagnetic interference design, adaptable to complex electromagnetic environments in PCB equipment. Optimized signal processing algorithms with strong noise resistance.

8. Intelligent and Automated

The CPD clamp-on flow sensor / flow meter can connect to the main control system of cleaning equipment via Modbus protocol, supporting remote calibration, data recording, and fault early warning. Supports multiple communication interfaces and industrial IoT integration, providing flow data support for equipment digital twins and smart factories.

Choose XY-TEK

In the trend toward more advanced and higher integration in PCB manufacturing and assembly, the requirements for PCB cleaning processes are becoming increasingly stringent.

The CPD clamp-on ultrasonic flow sensor, with its non-invasive, high-accuracy, fast-response, and ultra-pure advantages, provides an innovative flow measurement solution for PCB cleaning equipment.

Through the successful application in this customer's next-generation PCB cleaning equipment, the CPD clamp-on flow sensor / flow meters has become a core component for optimizing PCB cleaning equipment, providing solid technical support for the stability, consistency, and yield improvement of the customer's cleaning processes.

Currently, the customer's cleaning equipment has been successfully introduced into PCB manufacturing and assembly plants.

For more information on PCB cleaning flow measurement solutions, please contact the XY-TEK technical team at global@xy-tek.cn

Pre-Sale

Pre-Sale After-Sale

After-Sale