Blog

XY-TEK is a high-tech company specializing in the development, manufacturing, and sales of accurate and reliable ultrasonic flow sensors/flow meters. We specialize in flow rate measurement for small tubing and low flow rates in medical devices, bioprocessing, beverage and drink filling, industry automation, etc. XY-TEK also offers ultrasonic flow sensors, vortex flow meters, and bubble detectors OEM.

Clamp-on Ultrasonic Flow Sensors in Coating Equipment: Enhancing Glue Coating Accuracy and Consistency Gluing Coating Equipment

Gluing Coating Equipment Introduction

In the PCB manufacturing processes, coating equipment is responsible for uniformly coating the glue on the surface of the PCB. Through a accurate control system, high-viscosity glue (typically greater than 50 centipoise) is accurately dispensed onto the surface of PCB, etc., forming a uniform, defect-free glue layer that lays the foundation for subsequent processes.

Typical coating equipment includes glue supply modules, glue pumps, flow control modules, etc. The glue coating process demands extremely high accuracy, stability, and response speed in flow control, which directly impacts the quality of the coating and the quality of the PCB manufacturing.

Flow Rate Measurement Challenges for a Coating Equipment Customer

As a leading domestic manufacturer focused on the research and development of coating equipment, R company faced the following glue flow rate measurement challenges during the development of its next-generation coating equipment.

1. Insufficient Glue Volume Control Accuracy

Traditional invasive flow meters introduce pressure drops, affecting the stable output of glue pumps. Variations in glue viscosity (>50 centipoise) lead to flow measurement deviations. Fluctuations in glue flow directly impact the uniformity of the glue film on the silicon wafer surface, with film thickness deviations potentially exceeding process tolerances.

2. Cross-Contamination Risks

The invasive flow rate measurement flow sensor may introduce contamination into the coating process.

3. Bubble Interference

The pumping system tends to generate bubbles during liquid dispensing. Even tiny bubbles, once sprayed onto the PCB surface, can cause glue breaks or void defects, affecting coating precision. Bubbles introduced into the tubing result in actual glue application volumes falling below process values.

Bubbles cause uneven spraying, impacting the quality of the glue layer.

4. Equipment Maintenance and Reliability Challenges

Invasive flow sensors are prone to contamination by high-viscosity glue, potentially introducing particle pollution and requiring frequent cleaning and maintenance.

Traditional flow sensors / flow meters lack effective self-diagnostic mechanisms for faults. In cases of flow anomalies (such as bubbles or pump failures), the absence of rapid diagnosis and alarm mechanisms can lead to scrapping entire batches of products.

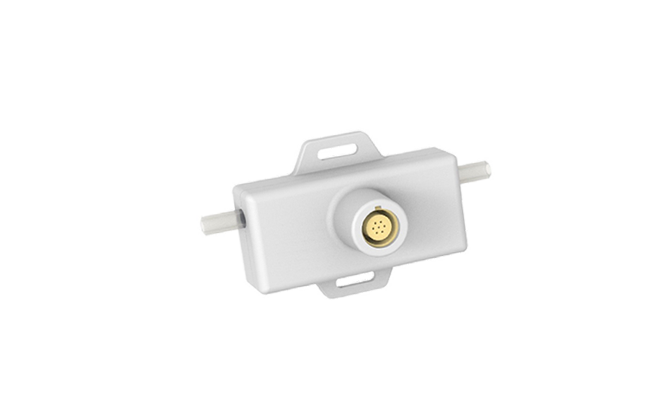

Application of CPD Clamp-on Ultrasonic Flow Meter in Coating Equipment

To address the above challenges, the customer adopted the CPD clamp-on ultrasonic flow sensor / flow meters as the core flow measurement component in its next-generation coating equipment, enabling visualized monitoring of glue flow at multiple key points.

1. Accurate Measurement of Photoresist Supply Flow Rate

The CPD clamp-on ultrasonic flow sensors / flow meters are installed in the tubing connecting the pump to detect glue flow rates in real time.

The flow sensors / flow meters connect to the controller, forming a closed-loop control system that ensures uniform discharge of the glue from the pump at a constant speed. The CPD flow measurement accuracy reaches ±0.1% FS, providing accurate feedback data for glue flow control.

2. Intelligent Control of Gluing Components

The gluing flow management module integrates the CPD clamp-on ultrasonic flow sensor / flow meters and control valves. The flow sensor acquires real-time glue flow rates or volumes during gluing, fully reflecting the actual gluing process. The control valves adjust the glue flow rate based on signals from the control mechanism, enabling real-time control of photoresist coating flow.

3. Bubble Detection and Alarming

The CPD ultrasonic flow meter features built-in bubble detection and alarming functions, utilizing the difference in ultrasonic propagation speeds between gases and liquids to detect bubbles in the tubing in real time. With multiple output methods integrated into a closed-loop control system, it triggers alarms upon bubble detection and promptly adjusts process parameters to prevent bubble contamination on the PCB surface, ensuring the coating quality.

Customer Value

1. Significant Improvement in Coating Accuracy and Quality

Glue flow rate measurement accuracy improved from ±5% to ±2%, with a notable enhancement in coating thickness uniformity.

2. Enhanced Coating Process Stability and Reliability

Real-time flow rate measurement ensures process stability and reduces fluctuations.

Non-contact measurement avoids contamination introduced by the flow sensor / flow meter, reducing overall maintenance costs for gluing and developing equipment.

Simultaneous monitoring by multiple flow sensors ensures that single-point flow failures do not affect overall equipment operation.

3. Reduced Operational Costs and Maintenance Frequency

Reduces waste of expensive glue materials due to inaccurate flow control

Avoids frequent cleaning and replacement of flow meters, significantly lowering equipment maintenance costs.

Reduces downtime caused by flow errors on production lines, improving overall equipment efficiency.

4. Support for Intelligent and Digital Upgrades in Coating Processes

Real-time flow data provides support for process optimization.

Supports remote monitoring and predictive maintenance, laying the foundation for next-generation intelligent gluing equipment.

Product Features of CPD Clamp-on Ultrasonic Flow Sensor / Flow Meter

1. True Non-invasive Flow Rate Measurement

The CPD clamp-on ultrasonic flow sensor / flow meter clamps onto the exterior of rigid plastic tubing such as PFA/PTFE, achieving "0 contact" with the glue and eliminating metal ion precipitation and particle contamination caused by insert-type flow sensors. It perfectly aligns with the high cleanliness requirements of the PCB assembly and manufacturing processes.

2. High Flow Rate Measurement Accuracy and Fast Response

Repeatability of ±0.1% FS, with millisecond-level response speed, capturing flow rate changes in real time to meet the needs of various precision coating processes.

Supports bidirectional flow measurement for comprehensive monitoring of photoresist flow status.

3. Excellent Medium Adaptability

Measurement accuracy is unaffected by photoresist viscosity (>50 centipoise), color, or transparency. Capable of measuring various media from low-viscosity solvents to high-viscosity glues.

4. Convenient Installation and Maintenance

Clamp-on installation requires no tubing cutting or production interruption. CPD ultrasonic flow sensors / flow meters support clamping on rigid tubing with outer diameters of 6-26mm. Compact size make the flow sensor / flow meter can be easily to install in space-constrained gluing equipment interiors.

5. Intelligent and Integrated Design

Equipped with real-time flow data reading software, supporting data recording and analysis. Multiple output interfaces (4-20mA, RS485, etc.) for easy automation integration. Corrosion-resistant housing materials, impact-resistant, suitable for harsh silicon wafer manufacturing environments.

6. Integrated Bubble Detection and Alarming

The integrated bubble detection function accurately identifies bubbles with diameters ≥1/3 of the tubing inner diameter. Collaborates with flow rate measurement to provide comprehensive monitoring of glue gas-liquid states.

Choose XY-TEK

In the trend toward more advanced processes in PCB assembly and manufacturing, the flow rate measurement accuracy of the coating equipment directly impacts product yield and performance. The CPD clamp-on ultrasonic flow meter, with its non-invasive and high-accuracy measurement advantages, provides a reliable flow monitoring solution for coating equipment.

Through the successful application in the customer's next-generation coating machine, the CPD clamp-on ultrasonic flow meter / flow sensor not only resolves the pain points of traditional flow rate measurement sensors but also provides solid technical support for the stability and reliability of the coating equipment through its intelligent and integrated design.

For more information on flow measurement solutions for coating equipment, please contact the XY-TEK flow sensor engineer team at global@xy-tek.cn

Pre-Sale

Pre-Sale After-Sale

After-Sale