- Home

- Products

- Medical

-

CG Series Clamp-on Ultrasonic Flow Sensors / Flow Meters

CG series ultrasonic clamp-on flow sensors / flow meters are compact in size, and can measure flow a...

-

CM series Clamp-on Ultrasonic Flow Sensor/Flow Meters

The CM series clamp-on ultrasonic flow sensors/flow meters are similar to the CG series flow sensors...

-

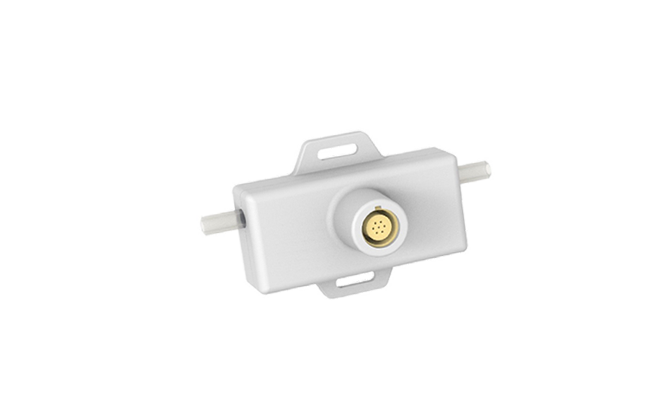

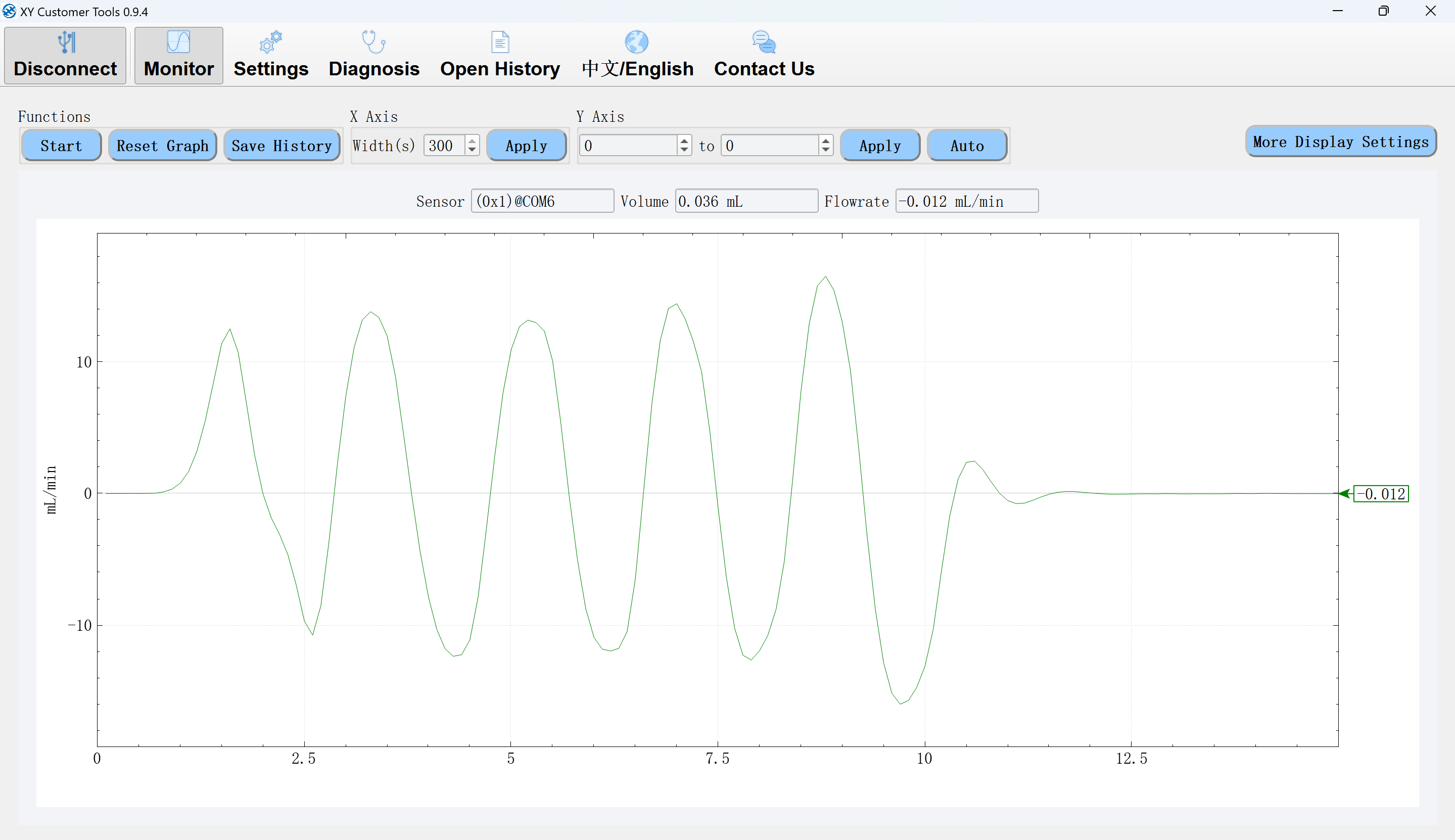

TH series Pulsatile Flow Sensor / Flow Meter

The TH series pulsatile flow rate measurement sensors/flow meters are designed specifically for hear...

-

- Bioprocess

-

CG series Clamp-on Ultrasonic Flow Sensor / Flow Meter

CG series clamp-on flow sensors / flow meters are compact in size, and can measure flow and output r...

-

TGU series Low-flow Ultrasonic Flow Sensor / Flow Meter

The TGU Series Low-flow Ultrasonic Flow Sensors / Flow Meters feature a U-shaped measuring channel d...

-

SU series Single-use Ultrasonic Flow Sensor / Flow Meter

The SU single-use ultrasonic flow sensor/flow meter incorporates a disposable measuring channel made...

-

- New Energy

-

CPD series Clamp-on Ultrasonic Flow Sensor / Flow Meter

The CPD series clamp-on ultrasonic flow sensor/flow meters boast a compact design with an integrated...

-

TPD series In-line Ultrasonic Flow Sensor/Flow Meter

The TPD series inline ultrasonic flow sensors/flow meters feature an integrated design with a built-...

-

TPK series In-line Ultrasonic Flow Sensor / Flow Meter

The TPK series inline ultrasonic flow sensors/flow meters feature an integrated design with a built-...

-

- Industrial Automation

-

CPD series Clamp-on Ultrasonic Flow Sensor / Flow Meter

The CPD series clamp-on ultrasonic flow sensor / flow meter boasts a compact design with an integrat...

-

TPD series In-line Ultrasonic Flow Sensor/Flow Meter

The TPD series inline ultrasonic flow sensors/flow meters feature an integrated design with a built-...

-

TPK series In-line Ultrasonic Flow Sensor/Flow Meter

The TPK series inline ultrasonic flow sensors/flow meters feature an integrated design with a built-...

-

- Accessories

- Medical

- Applications

- Resources

- News

- Company

Pre-Sale

Pre-Sale After-Sale

After-Sale