-

Do CG and CM series flow sensors have medical-related certifications?

CG and CM series flow sensors are measurement components, not medical devices, so they do not require standalone medical certifications. The CG and CM series flow sensors / flow meters are typically integrated into the customer’s medical device for certification.

2025-12-22

-

Does XY-TEK hold relevant certifications such as ISO 9001, ISO 13485, CE marking, or FDA approval?

ISO 9001 has been certified. CE certification is included in the application plan. FDA is a U.S. medical certification; the CG and CM series do not apply for FDA certification on their own and are generally certified together with the customer’s medical device.

2025-12-22

-

Are the CG and CM series flow sensor / flow meters suitable for hospital/operating-room environments, and can they withstand common wipe disinfectants?

The CM series flow sensors are suitable for hospital/OR environments. Its surface is anodized and can withstand wiping with alcohol and similar disinfectants.

2025-12-22

-

Is the CM series flow sensors/flow meters designed according to IEC 60601 and ISO 13485?

The CM series complies with the IEC 60601 medical safety standard.

2025-12-22

-

Does the CM series flow sensors / flow meters internal software comply with IEC 62304 Class B (or Class C)?

In the initial design, the CM series flow sensors was not developed to IEC 62304 Class B or Class C. However, CM series sensors are now widely used in medical equipment. Future versions will be developed in accordance with IEC 62304 B/C.

2025-12-22

-

If pursuing medical-use certification for an OEM sensor, what is the approximate cost for EMC and medical safety certification?

The EMC and medical safety certification will depend on the chosen certification institution. A formal quotation can be provided if needed.

2025-12-22

-

If pursuing medical-use certification for an OEM sensor, which safety standards must the medical OEM flow sensor follow?

XY-TEK can provide sample medical safety certification documents from existing customers for reference.

2025-12-22

-

If pursuing medical-use certification for an OEM sensor, what is the estimated timeline?

It depends on the specific case and requires case-by-case analysis.

2025-12-22

-

Does XY-TEK provide calibration certificates for flow sensors?

Yes.

2025-12-22

-

What type of calibration certificate is provided: manufacturer certificate/factory calibration report or third-party laboratory certificate?

By default, XY-TEK provides a factory calibration certificate (free of charge).

Third-party laboratory certificates are available upon request (additional cost).

2025-12-22

-

Can XY-TEK provide documents such as datasheets, risk analysis reports, user manuals, etc. for local evaluation?

Yes.

2025-12-22

-

Can XY-TEK provide 3D models or drawings of the flow sensor / flow meters?

They can be provided depending on the evaluation.

2025-12-22

-

Does XY-TEK provide integration support for developers who want to integrate the flow sensor / flow meters into their own systems?

Yes—both online and on-site support are available.

2025-12-22

-

Does XY-TEK sell flow sensors / flow meter / bubble detectors outside China (e.g., Europe, Southeast Asia)?

Yes.

2025-12-22

-

Does XY-TEK open to develop new distributors and strategic partnership relationships?

Yes.

2025-12-22

-

Does XY-TEK offer private label or OEM customization services?

Yes, subject to certain prerequisites. Please contact the sales team at global@xy-tek.cn for details.

2025-12-22

-

What support does XY-TEK provide to distributor partners, such as marketing materials, technical training, and after-sales service?

Marketing material support, regular product training, regular technical training, and technical support for registered customers, etc.

2025-12-22

-

What is the global sales performance?

XY-TEK flow sensor/flow meter products have been sold to 30+ countries and regions worldwide. Sales revenue information is not publicly disclosed.

2025-12-22

-

Is there a minimum order quantity flow sensors / flowmeters / bubble detectors (MOQ)? No MOQ.

No MOQ.

2025-12-22

-

What is the production lead time for orders?

Typically 4–6 weeks.

2025-12-22

-

What is the delivery lead time of the XY-TEK flow sensor / flow meters?

In stock: shipped within 10 business days

Out of stock: lead time approx. 4–6 weeks

2025-12-22

-

What are the prepayment terms?

Full payment in advance; shipment after payment is received.

2025-12-22

-

Are all the flow sensor / flowmeters manufactured by XY-TEK?

Yes. All flow sensor / flow meter / bubble detector products are independently developed and manufactured by XY-TEK.

2025-12-22

-

Can customers visit the XY-TEK manufacturing factory?

Yes, but an appointment with the sales team must be scheduled and confirmed in advance, and a confirmation email/message must be obtained.

2025-12-22

-

After-sales service: warranty period, RMA process, and availability of technical support

Flow sensor / flow meter products come with a 1-year warranty (consumables excluded).

Within the warranty period, issues caused by product quality will be repaired or replaced free of charge. After the warranty period, repair will be charged depending on the situation.

All products are inspected and accepted in accordance with the XY-TEK shipment standards. If the customer has any objections, please raise them within 5 days of receiving the products.

XY-TEK provides comprehensive technical support and RMA return/exchange/repair service.

2025-12-22

-

Introduction to Non-Contact Flow Detection

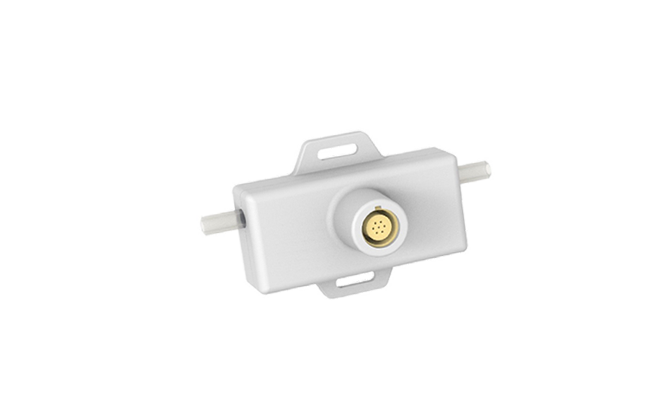

A non-contact flow sensor utilizes ultrasonic technology to measure flow rate at critical points of various biotech processes. Ultrasonic technology enables non-contact detection of flow, independent of liquid composition (color, viscosity, turbidity, charge, temperature, etc.).

XY-TEK’s ultrasonic flow sensors clamp onto the outside of flexible or rigid tubing, send the ultrasonic signal through the tubing, and directly measure flow while simultaneously calculating the total volume dispensed.

The addition of real-time flow measurement allows for increased insight into critical process parameters (CPP) that are necessary for optimal batch-to-batch consistency and reliability. By non-invasively monitoring a process, setup time can be reduced by eliminating the need for in-line sensor design.

In recent years, the biotech industry has shifted priorities toward maximizing process intensification by utilizing complete single-use systems. That very single-use process requires sterility at the point of delivery.

This limits the number of process analytical technology (PAT) devices that can be integrated. By adding a non-invasive flow sensor, a single-use process can still be intensified without additional validation of materials and complexity of design.

2024-07-30

-

Application of Non-contact Flow Detection in Medical Devices

In a lot of medical devices and life support systems such as hemodialysis machines, artificial heart, organ transplantation systems, heart-lung machines, ECOM, and surgical robots, it is necessary to monitor the flow rate of blood, saline, urine, and liquid drugs to improve system safety and patients’ health.

XT-TEK non-contact flow sensors / flow meters can measure flow in small tubing at low flow rates, and they are easy to install and disassemble. The sensors measure flow accurately and help identify potential risks in various medical operations.

For example, they can detect failures of dialysis equipment or flow connectors during surgery, and low blood flow and thrombosis in AVF/AVG caused by narrowing of blood vessels. They can monitor the status of pumps and the aging of tubing. All these help clinicians obtain more accurate diagnoses and avoid human operation errors on site.

In recent years, with the advancement of intelligent medical devices, the demand for non-invasive flow measurements is increasing quickly, not just in medical institutions, but also in daily home care and remote treatments.

2024-07-30

-

How does a clamp-on ultrasonic flow sensor / flow meter work?

An ultrasonic flow sensor utilizes the transit-time difference technology to non-invasively measure flow rates within flexible or rigid tubing. Ultrasound waves are propagated by matter and are sensitive to changes in such matter. These changes seen between the emitted ultrasound waves and received ultrasound waves are directly related to the velocity of any given liquid and allow for the calculation of the total volume.

The upstream and downstream sensors are piezoelectric crystals that transmit and receive the ultrasonic signal. The ultrasonic waves then propagate through the liquid at an angle relative to the axis of the tubing. The transit time in the upstream direction is always larger than that in the downstream direction when there is flow. The time difference in both directions is proportional to the mean flow velocity, and together with the tubing cross-section area information, the volume flow rate can be derived.

Additionally, since the XY-TEK flow sensor includes an upstream and downstream sensor element, it can measure bidirectionally.

2024-07-30

-

What are the tubing requirements of a clamp-on flow sensor?

A clamp-on flow sensor works with the most flexible tubing on the market. The most important aspect to consider when selecting a sensor is the Outer Diameter (OD).

For flexible tubing, sensors typically range in size from 0.25 inches up to 2 inches OD.

Another detail to consider is that the Inner Diameter (ID) must not be less than 50% of the OD. If the ID is less than 50% of the OD, the wall thickness is too great and the flow path is too small for accurate flow measurements.

Other metrics to consider when selecting an XY-TEK flow sensor–or any non-contact flow sensor – include tubing material, process temperature, fluid type, and flow rate.

2024-07-30

-

How accurate are non-invasive flow sensors / flow meters?

Current non-invasive flow sensors on the market will offer on average +/-5% accuracy, based on a flow volume verification via a scale or graduated cylinder. In process and with a custom calibration to tubing type, fluid, and temperature, that accuracy can typically be improved.

XY-TEK's flow sensors can measure with +/-5% accuracy when the flow rate is less than 100mL/min, depending on the tubing size. Greater flow rates (>100mL/min) can consistently produce +/-3% accuracy.

The higher the flow rate, the greater the transit-time difference is measured, allowing for increased accuracy. Also, higher accuracy and repeatability can be realized with a custom calibration.

2024-07-30

-

What are common applications for a clamp-on flow sensor / flow meters?

Essentially, anywhere flow is desired to be measured and controlled during a process that utilizes flexible or rigid tubing.

This includes buffer & media preparation/manufacturing, perfusion, fermentation, cell culture, fill & finish dosing, TFF & chromatography skids, peristaltic pump performance monitoring, bioreactor harvest, artificial heart operation, hemodialysis machines, organ transplantation, blood pump, and many more. The XY-TEK flow sensor / flow meters can be a valuable addition to process intensification and PAT initiatives.

2024-07-30

-

Can the XY-TEK ultrasonic flow sensors / flow meters detect air bubbles?

Yes.

When more than 50% of the tubing is filled with air bubble, the XY-TEK ultrasonic flow sensor / flow meters will provide a steady 0mL/min signal. This output can be configured within a control strategy to present an alarm or process data point that indicates air is present within a process. This can enhance process quality control and be used as a safety measure.

2024-07-30

-

Does the XY-TEK clamp-on flow sensors / flow meters come calibrated?

Yes.

It is industry standard to provide a factory calibration for new flow sensors. This calibration is then further strengthened once in the process by applying tubing type, fluid type, flow rate range, and process temperature to the sensor correction factors. By calibrating a clamp-on flow sensor / flow meters to users specific application details, very high accuracy and repeatability can be realized.

All XY-TEK Flow sensors / flow meters come factory-calibrated across their entire operational flow range. Flow Viewer software allows end users to modify this calibration as needed to provide additional accuracy.

With the help of XY-TEK engineering team, a clamp-on flow sensor can be calibrated to users application details. Up to 8 calibration factors can be saved and readily accessed to provide a wide range of accuracy for changing processes. These calibrations are saved directly to the sensor's internal memory, allowing for plug-and-play functionality.

2024-07-30

Pre-Sale

Pre-Sale After-Sale

After-Sale