Medical dialysis devices can be divided into two types: hemodialysis and peritoneal dialysis.

The dialysis system removing harmful substances from the body's fluids through a semi-permeable membrane, making it the most effective treatment for kidney failure.

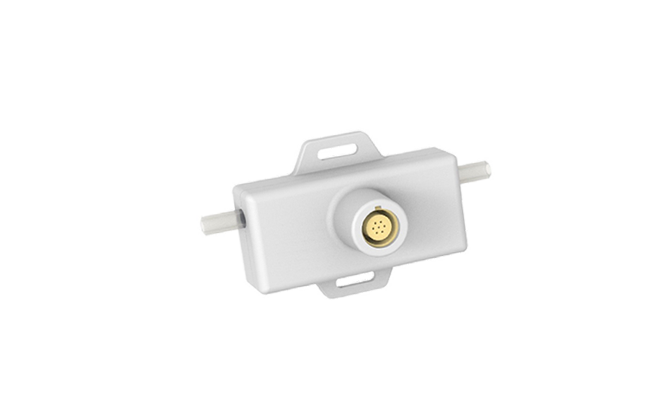

Hemodialysis utilizes a dialysis machine to draw the patient's blood through a disposable tubing system into a dialyzer, where the dialysis process occurs before the blood is re-infused into the patient's body. CG series ultrasonic flow sensors/ flow meters can monitor the normal operation of the blood pump by measuring the flow rate in real-time and provide early warnings for any blockages or air bubbles in the tubing.

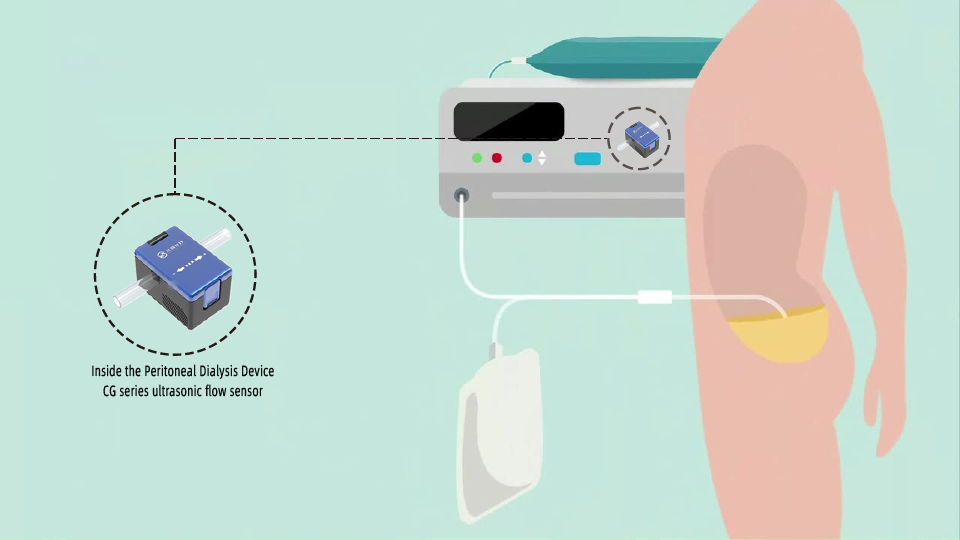

Similarly, when fully automatic peritoneal dialysis machines use peristaltic pumps to control the flow rate and volume of the dialysis solution, CG series ultrasonic flow sensors/flow meters can measure the flow rate of the peristaltic pumps to guarantee the normal operation of the peritoneal devices.

Pre-Sale

Pre-Sale After-Sale

After-Sale