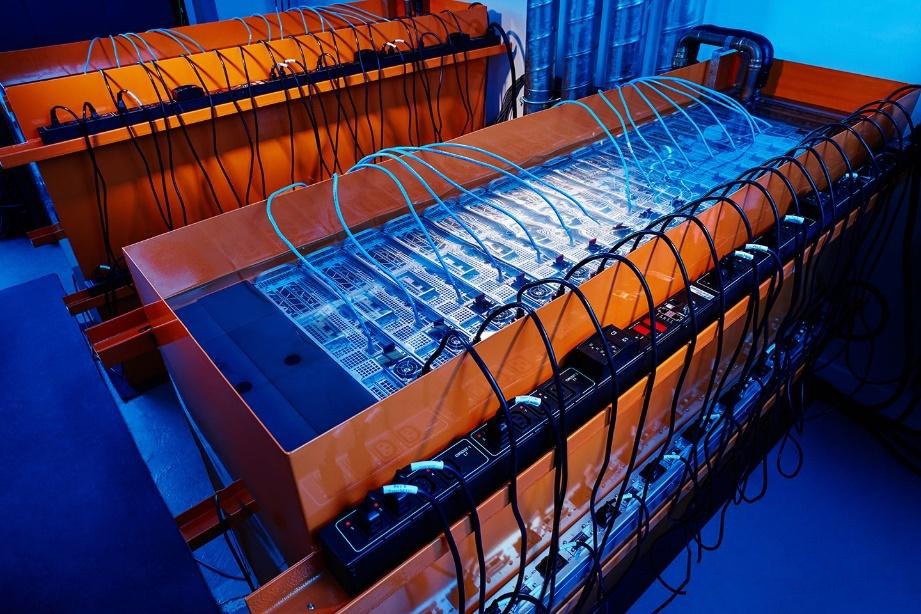

Liquid Cooling is a way of dissipating heat from electronic devices. It absorbs the heat generated by the device bypassing the cooling medium (which may be water or other coolant) through the radiator of the electronic device, taking the heat away, thereby reducing the temperature of the device.

Liquid cooling systems are increasingly used in various industries, including HPC, data centers, industrial machinery, power batteries, energy storage batteries, etc. due to their superior thermal management efficiency compared to traditional air cooling methods.

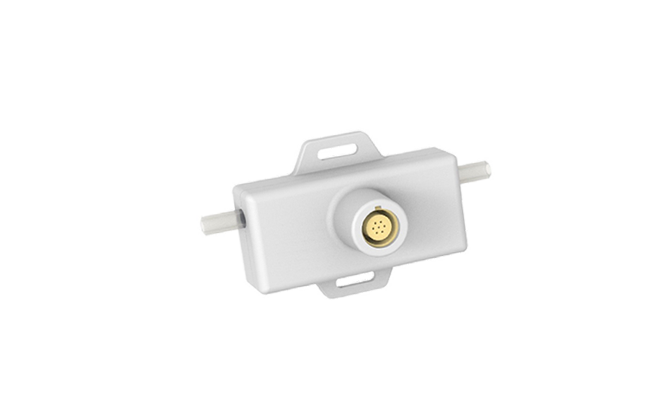

TGD series inline ultrasonic flow sensors / flow meters play a crucial role in optimizing the performance of these liquid cooling systems by providing reliable and accurate flow measurements.

Pre-Sale

Pre-Sale After-Sale

After-Sale